How Does a Torque Sensor Work in an E-Bike?

Sales Director of KEREN Electric

Table of Contents

The evolution of the electric bicycle (e-bike) has transitioned from simple motorized transportation to a sophisticated synergy between human effort and machine intelligence. At the heart of this revolution lies the torque sensor.

As a professional manufacturer at Keren Electric, we specialize in the high-precision engineering required to make e-bikes feel less like “scooters” and more like an extension of the rider’s own body. In this technical deep dive, we will explore the mechanics of torque sensing, its advantages over traditional cadence systems, and how it optimizes both battery efficiency and rider health.

How Does a Torque Sensor Work in an E-Bike?

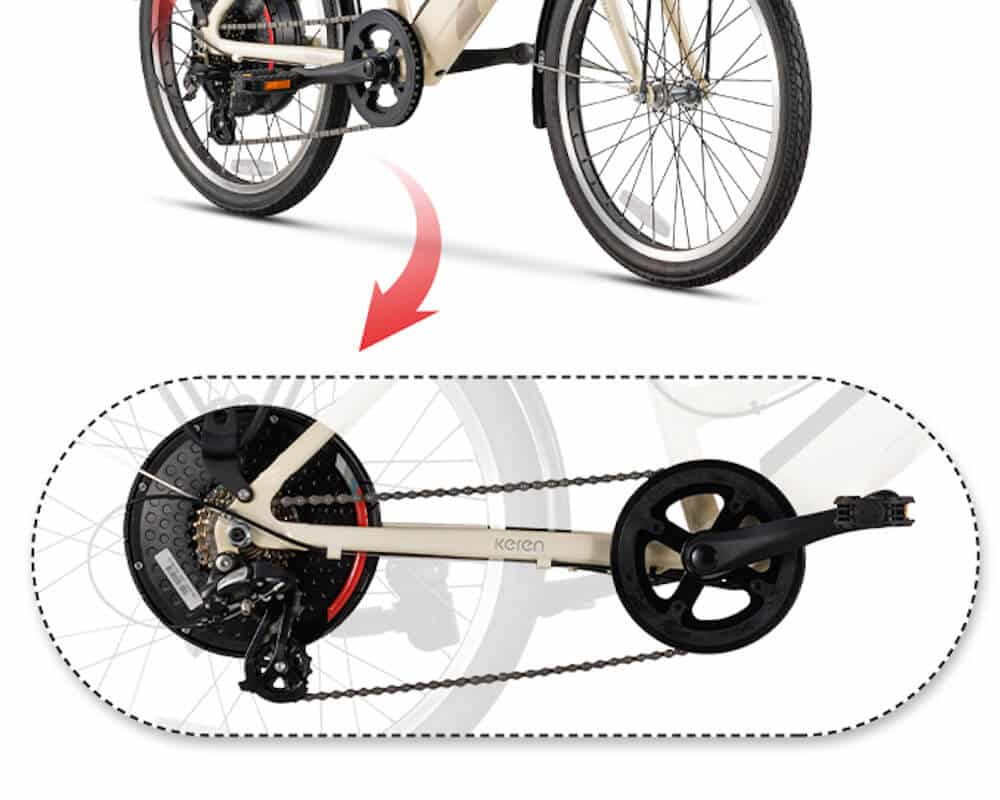

Torque sensors measure the force the rider applies while pedaling. Rather than simply sensing whether the pedals are turning, they continuously measure pedal pressure and translate that data into proportional motor assistance.

This technology allows the motor to behave like an extension of the rider’s legs, delivering the exact amount of power when and how it’s needed.

1: Even if the pedals are not moving, the bicycle can detect the force you exert.

2: It measures force accurately in real time. The more force you exert, the more power the motor receives. The lighter the force, the less power the motor receives.

3: Protect your knees from the very first step! All our e-bikes are equipped with a torque sensor assist system to help you ride healthily with every step!

What is torque in the context of e-bikes?

Torque refers to the rotational force that is applied to the crank, bottom bracket, or rear hub when a rider pedals. In e-bikes, this force determines how much effort the rider is putting in at any given time.

A torque sensor converts this mechanical force into an electrical signal. The e-bike controller then uses this signal to calculate the exact amount of motor assistance required, resulting in a seamless blend of human and electric power.

Torque sensor vs. cadence sensor

- Cadence sensors detect pedal rotation but do not measure power. If the pedals are moving, the motor provides a predetermined level of assistance regardless of effort.

- Torque sensors, in contrast, measure how hard the rider is pedaling. Light pressure produces light assistance, while firmer pedaling activates more motor power. This difference explains why torque sensor e-bikes feel more natural and responsive.

Key components of an e-bike torque sensor system

The torque sensor system in an e-bike comprises several precise components that work together to measure rider effort and convert it into controlled motor assistance. For precise force detection, seamless power delivery, and dependable long-term performance, each component is essential.

Strain gauges

Strain gauges are the primary sensing elements that detect pedaling force. They are highly sensitive electrical components that change resistance under mechanical stress.

When a rider applies pressure to the pedals, a slight deformation occurs in the crankshaft or axle. This tiny shift is picked up by strain gauges, which then translate it into an electrical signal proportionate to the torque delivered.

Torque sensor shaft or axle

The sensor shaft or axle is the mechanical part that directly experiences the rider’s pedaling force. It is designed to bend slightly under load while maintaining structural strength.

This controlled flexibility allows for accurate force measurement without compromising durability, making it essential for consistent torque detection over long periods of use.

Signal conditioning circuit

The electrical signals generated by strain gauges are tiny and susceptible to noise. The signal conditioning circuit amplifies, stabilizes, and filters these signals before transmission.

This ensures accurate torque readings even during rapid pedaling changes, uneven terrain, or high-vibration riding conditions.

Microcontroller or sensor processor

The microcontroller processes torque data in real time. It interprets the conditioned signal and converts it into digital information for the e-bike controller.

High-quality processors enable fast response times, allowing the motor to react quickly to changes in pedaling force.

Wiring and data interface

Wiring and connectors transmit torque data from the sensor to the e-bike controller. These components must be shielded and well-insulated to prevent signal loss or interference.

Reliable data transmission ensures continuous communication between the sensor, controller, and motor under all riding conditions.

Protective housing

The protective housing encloses the torque sensor components and protects them from water, dust, heat, and mechanical impacts.

Well-sealed housings improve durability and performance stability, especially for riders who use their e-bikes in harsh or variable environments.

The Engineering Behind the Magic: Precision Strain Gauges

While a basic cadence sensor simply counts how many times the pedals spin per minute, a torque sensor measures how hard you are pushing. It does this using a component called a precision strain gauge.

The Physics of Measurement

A strain gauge is an extremely sensitive electrical sensor. When you apply pressure to the pedals, the metal of the axle or the crank arm undergoes a microscopic amount of deformation (bending). Although this movement is invisible to the human eye, the strain gauge detects the change in electrical resistance caused by this deformation.

Real-Time Data Processing

The sensor captures this data at an incredible frequency—often hundreds of times per second. This information is sent to the e-bike’s controller (the “brain”), which then calculates exactly how much current to send to the motor.

Static Force Detection

One of the most significant advantages of Keren Electric’s torque sensors is static force detection. In a cadence-based system, the bike must move (usually half a rotation of the pedals) before the motor engages.

- The Torque Advantage: Even if the pedals are not moving—for instance, when you are stopped at a red light on an uphill slope—the sensor can detect the weight of your foot on the pedal. The moment you apply pressure, the motor provides instant support. This eliminates the “lag” that often leads to wobbling or struggle when starting from a standstill.

Why Keren Electric?

The market is flooded with sensors, but not all sensors are created equal. Keren Electric has invested years into the research and development of high-sensitivity alloys and proprietary algorithms that filter out “noise” (such as vibrations from a bumpy road) to ensure the sensor only reacts to your intended force.

Our Commitment to Quality:

- Precision Calibration: Every sensor is calibrated to ensure a 1:1 ratio between effort and assistance.

- Durability: Our sensors are sealed against dust, mud, and water, ensuring that the precision strain gauges remain accurate for years of heavy use.

- The “Natural” Feel: We pride ourselves on creating a ride that feels intuitive. You won’t feel the motor “taking over”—you will simply feel stronger.

Conclusion: The Future of Your Ride

The torque sensor is the difference between a bicycle with a motor and a truly intelligent electric vehicle. It is the bridge between human intent and mechanical execution. By choosing a Keren Electric bike equipped with our advanced torque sensing technology, you are choosing:

- Instantaneous Power that reacts to your needs.

- Optimized Range that lets you go further on a single charge.

- Ergonomic Safety that protects your joints and enhances your health.

We invite you to visit our showroom and experience the difference for yourself. Once you feel the smooth, powerful, and intuitive assistance of a Keren Electric torque sensor, you will never want to ride a standard e-bike again.

Frequestly Asked Question

1.What is a torque sensor in an e-bike?

A torque sensor measures the force the rider applies to the pedals. It communicates with the motor to assist in proportion to the rider’s effort, creating a smooth, natural riding experience.

2. How is a torque sensor different from a speed sensor?

Speed sensors detect wheel rotation and provide motor assistance solely based on speed. Torque sensors, on the other hand, measure pedaling force, allowing the motor to dynamically respond to the rider’s effort for smoother and more efficient support.

3.What are the benefits of having a torque sensor on an e-bike?

Torque sensors improve ride quality by providing seamless pedal assistance, increasing safety through controlled acceleration and deceleration, improving battery usage, reducing wear on bike components, and supporting fitness and recovery goals.

4.Are torque sensors useful for all types of e-bikes?

Yes, torque sensors benefit urban commuters, mountain bikes, cargo e-bikes, and recreational e-bikes. They provide adaptive motor assistance based on the rider’s effort and terrain, making every ride smoother and more efficient.

5.How does a torque sensor improve safety?

By providing motor assistance proportional to pedaling force, torque sensors prevent sudden surges, support controlled braking, reduce joint stress, and maintain stability on uneven terrain, making riding safe in urban and off-road conditions.

Latest News

Request A Quote

More About Keren

Best E-bike Manufacturers

Related Products

Keren Electric, based in China, specializes in the production of electric scooters and features a variety of models designed in-house.